Grain vs Silage

Breeding for Grain

Approximately 92% of corn acres are grown for grain. In order for a grain hybrid to perform, it must have durable kernels that will stay intact during combining, shipping and elevating. These kernels must also dry quickly to save on the cost of mechanical drying. To ensure the successful harvest of a grain crop, breeders select grain hybrids to have stiff stalks that will stand late into the season. These hybrids are also designed to have a relatively high ear placement on the plant for ease of combining. Grain farmers are paid on the basis of kernel integrity, test weight and kernel moisture. To meet this bill, a successful grain hybrid must have three key kernel characteristics: They must have a vitreous, or glass-like kernel type, which makes them hard, tough and heavy. These kernels must be relatively small to further reduce the likelihood that they will fracture during mechanical processing, and they must dry rapidly on the plant as it reaches maturity to save on drying costs. Grain-type hybrids, with their small, fast drying, vitreous kernels, are ideal for delivering high quantities of starch in compact transportable packages to distant markets.

Dual purpose hybrids bred for grain do not make ideal silage. Here's why:

The starch

As a grain hybrid reaches silage maturity, its kernels dry rapidly and get very hard. This rapid drying creates a very narrow silage harvest window, which is further complicated by the extended stay green of the grain hybrid's stalk. Often, when the kernels reach a silage appropriate moisture, the plants are far too green and wet to put in the bunker. If the plant is harvested once the plant reaches silage-appropriate moisture levels, the kernels have likely become hard and dry. While the kernels may have a high starch test weight, they remain whole or fracture into large pieces during silage harvest and cow chewing. In this form, much of the starch is unavailable in the rumen for milk production.

In order to soften these large hard chunks of starch, a minimum storage period of six months is recommended. This long storage period increases storage space requirements and dry matter losses, and does not guarantee ideal starch quality by the time it is fed. Starch can be made more digestible by processing, but this damages eff ective fi ber and does not consistently reduce starch to a particle size that is comparable with a hybrid that has a more digestible kernel type.

Breeding for Silage

Roughly 8% of corn acres are grown for corn silage. In this application, ideal harvest occurs when the crop has reached 65% moisture and 50% kernel milk line. During this harvest window, the whole plant is cut low to the ground and is chopped into small pieces before being compacted into a silo or bunker, ensiled, mixed into a TMR and fed to dairy cows for a season or more. Given this process, an ideal silage hybrid must satisfy an entirely diff erent set of parameters than a grain hybrid. It must have a high total plant yield of digestible starch and fi ber, a long harvest window in which the plant dries to the appropriate moisture and remains there for an extended period, adequate sugars to promote fermentation, and a relatively short storage period to save on space and reduce dry matter losses. Ultimately, a corn silage hybrid must produce a robust, reliable, digestible crop that will promote rumination and readily produce high quality milk when mixed into a TMR and fed to a lactating cow.

Ideal Silage

The fiber

A successful grain hybrid is bred to withstand the elements until late season harvest, which requires the stalk to be stiff and solid. In addition, its ear must be positioned high on the plant to ensure successful harvest by the combine. Both of these requirements reduce fi ber digestibility. The ear is the heaviest part of the plant, so the below ear portion of the stalk must be heavily lignifi ed in order to support it. By raising the ear position and selecting for stiff stalks, grain hybrids produce a high proportion of indigestible fi ber.

It can be diffi cult to harvest a grain hybrid for silage when its stalk is at the appropriate moisture level. It can pass from too wet to too dry rapidly and this reduces silage quality and feed effi ciency. Excessively wet or dry silages often result in inadequate fermentation and unstable silage products.

Choose a hybrid that was bred for silage. Choose a Leafy!

| Ideal Grain | Ideal Silage | |

| Yield | High grain yield with high test weight. | High total plant yield of digestible forage. |

| Kernel Moisture | As dry as possible at grain harvest time. | 50% milk line for as long as possible at silage harvest time. |

| Kernel Hardness | As hard as possible to decrease possibility of breakage. | Soft and easily broken for maximum digestion in the rumen. |

| Kernel Size | Small to decrease possibility of breakage. | Large to increase possibility of breakage. |

| Stalk Moisture | Wet to keep plant alive as long as possible to reach ideal grain harvest. | Dries to achieve 65% total plant moisture and stays in that range to extend harvest window. |

| Stalk Integrity | As stiff and solid as possible for late season grain harvest. | As soft and fl exible as possible, yet strong enough to remain standing through late silage harvest. |

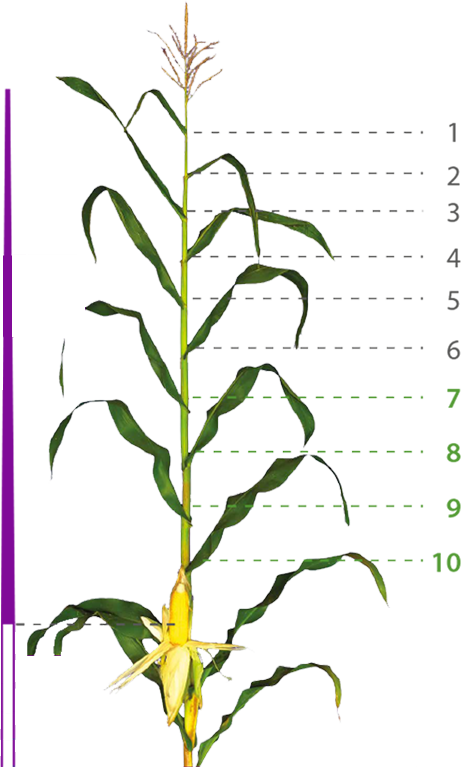

| Ear Height | High position on the plant to ensure harvest by combine. | Low position on the plant to increase proportion of digestible fi ber above the ear. |

| Ideal At Harvest | Wet strong stalk that supports ears of vitreous, hard, dry kernels. | Large plant with a soft stalk and moist ear of large breakable kernels. Stalk and ear dry at a complimentary rate. |